24/02/2016

At Carlton Services, our team of expert engineers specialise in keeping your refrigerators in full working order all year round. In our previous articles, we’ve looked at how refrigerators are recycled, top tips to keep them running efficiently and how they work. In this latest post, we present an interesting overview of how refrigerators are made.

Icy Beginnings

The original concept of refrigeration for food began with ice. For centuries, humans have recognised the use of ice to cool and preserve food. In fact – whilst it may sound unlikely- the ancient Indians and Egyptians were amongst the first to discover the principle.

Observers noted that whilst the Egyptian deserts were intensely hot during the day, when darkness fell temperatures could fall low enough to cause death.

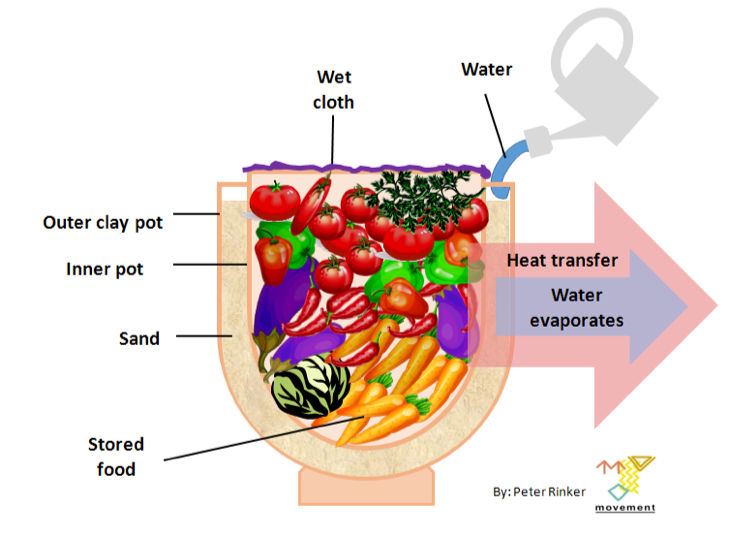

Whilst the low temperatures at night were known to be bad for the health, it was soon realised that the very same phenomena could be used to preserve food. It was discovered that if trays of water were placed outside, ice would form. This ice was then used to pack food to retain its freshness during the day. As research continued, it was discovered that the same principle could be artificially recreated in the daytime using the technique of evaporation.

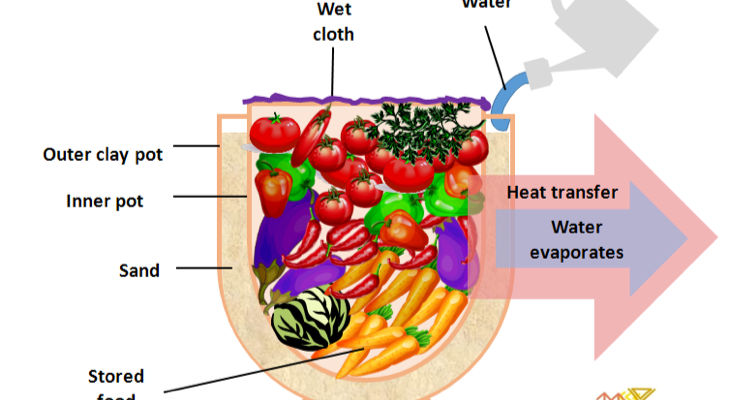

Archaeological findings indicate that this method was in use as early as 2500B.C. Frescos show slaves fanning water jars, which would increase air flow around the porous jars and aid evaporation, cooling the contents. These jars exist even today and are called “zeer”, hence the name of the pot cooler.

At the same time, the ancient Chinese had come up with a different way of achieving the same effect – they simply went to the mountains and collected the ice they required!

Once the application of ice had been discovered, attention shifted to storing ice. It was soon obvious that using insulated underground store rooms allowed low temperatures to be maintained for extended periods – which later led to the popularity of ice-houses, essentially a primitive version of the refrigerator as we know it today.

Yesteryear’s refrigerator – The ice house entrance, Eglinton Country Park, Scotland, United Kingdom

Did You Know?

Unlike many appliances, which exist purely for convenience or entertainment, refrigerators are truly critical. Approximately 50 percent of the world’s food would rot without insulated refrigeration.

The key to effectively maintaining a constant, controlled temperature was insulation. The first form of insulation in ice houses was straw, wood and even sawdust! Modern refrigerators are thankfully somewhat more hygienic!

Believe it or not, ice-houses remained in use in the UK until as late as the 1950’s, with ice typically imported from Scandinavia.

As early domestic refrigerators were invented, alternative insulation materials were explored, and eventually fibreglass became the material of choice for several years.

Unfortunately, fibreglass insulation had a tendency to allow water to leak, resulting in thermal transfer and loss of its effectiveness.

Today, refrigerators are insulated with rigid polyurethane insulating foam. Because of its effectiveness in keeping refrigerators and freezers cold, this material makes a significant contribution to sustainability and energy efficiency

Why Polyurethane?

Polyurethanes are ideal for the insulation of refrigerating appliances and have major advantages as they are:

- excellent insulators

- structurally strong thanks to the rigidity of the foam and adhesion of external skins (plastic and metal)

- the most cost-effective manufacturing solution, with multiple operations combined into one

- effective in confined spaces, allowing the maximum amount of food to be stored

- safe

- robust and strong

- very light, thus reducing transportation costs

- affordable, keeping the costs of refrigerators and freezers down

This means that ever more stringent energy standards can be met, with benefits to the consumer through lower energy bills and a reduction in energy used. In fact, Polyurethane is now estimated to have reduced energy consumption of refrigerators by over 60% since 1990.*

The Science of Evaporation

Whilst the ancient Egyptians had discovered the effects of evaporation in forming ice, it was not until many years later that the real science behind this process was fully understood.

It was in 1748 that a scientist by the name of William Cullen began investigating the evaporation process and how to speed it up by boiling ether into into a partial vacuum. These early experiments were followed by other scientists, and the concept of truly artificial refrigeration was born.

How does evaporation work?

Ever wondered why you feel cold as you get out of the swimming pool, even on a hot day? That’s evaporation in action: the water on your skin evaporates, taking heat energy from your skin, and using it to break the hydrogen bonds between water molecules as the liquid turns to vapour.

Evaporation occurs when there is sufficient energy to enable the fastest moving molecules to break the inter-molecular bonds in a liquid at its surface.

Since the temperature we measure depends on the average speed of the molecules, if the faster molecules escape from the liquid the average molecular speed is reduced and the temperature falls. The hotter the liquid, the more molecules there are moving rapidly so the faster it evaporates and the greater the cooling effect.

To speed up evaporation, we can use a second liquid to increase the rate of energy transfer – the concept behind refrigerant gasses.

Fancy having a go yourself? The Open University has a great Ice Making Challenge you can try.

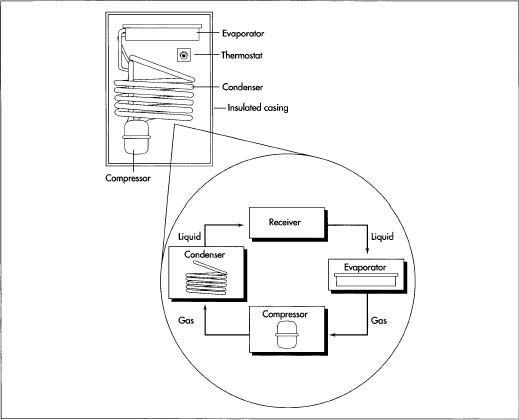

It was the discovery that different chemicals had different speeds of evaporation that led to the invention of the key components of a modern day refrigerator – the condenser, compressor and evaporator.

The first chemical to be used was Ethyl Ether, due to its property of evaporating faster than water. Subsequent experiments in America used Ammonia – which resulted in the discovery of the compression process that is so important to a modern day refrigerator.

Unfortunately, Ammonia is both odorous and dangerous. Research quickly shifted to finding a safer and more desirable alternative. The result was Freon, which remained the refrigerant of choice until environmental concerns were raised in the 1970’s.

Today, most refrigerators use a new gas known as R134a or Tetrafluoroethane, which has a much smaller impact on ozone depletion than its predecessors.

So how does a modern refrigerator work?

- Gas is drawn at low pressure and low temperature through a line.

- The gas is compressed using electricity to a higher pressure and its temperature rises (just like a bicycle pump which gets warmer when you are pumping up a tyre).

- It is then transferred to a condenser where the heat is removed and the gas begins to condense into a liquid.

- The heat is released via cooling fins on the back of the fridge unit. The liquid then goes through an expansion device where its pressure is suddenly lowered, it expands and some of the liquid turns very quickly into a vapour.

- This change of state has a cooling effect. Now the cold vapour and liquid are able to cool the air in the cabinet of the refrigerator through an evaporator.

- The liquid absorbs the warmth from the air inside the refrigerator and turns back into a low temperature gas, at low pressure. It now starts its journey again through the compressor.

Learn more at https://home.howstuffworks.com/refrigerator.htm

The Manufacturing Process

Outer Cabinet

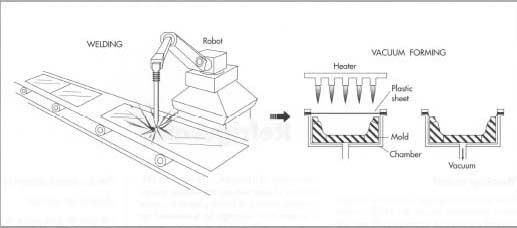

The outer cabinet is formed through a process of folding and sealing sheet metal. Once the correct shape has been made, the edges are either welded or clinched. Clinching involves crimping the two pieces together. Welded joints can be ground to make the joins disappear, so that the final cabinet has the appearance of being formed from a single, continuous piece.

Whereas domestic refrigerators are usually coated or painted (hence the term ‘white goods’), commercial refrigerator cabinets are typically stainless steel for maximum hygiene.

The outer cabinet and door, made of sheet metal, are either welded or clinched together. While some manufacturers also use sheet metal for the inner cabinet, some manufacturers and some models use plastic for inner liners. The plastic liners are made by vacuum forming. In this process, a thick piece of plastic slightly larger than the finished part has its outer edges clamped and is then heated. The hot plastic is next pulled by vacuum into a mold and cooled. After trimming, the resulting part is ready for assembly.

Source: https://www.madehow.com/Volume-1/Refrigerator.html

Read more: https://www.madehow.com/Volume-1/Refrigerator.html#ixzz40tOaLzZW

Inner Cabinet

In some models, the inner cabinet may be made of sheet metal in the same fashion as the outer cabinet, however the majority of refrigerators now have plastic interiors. The inner door, for example, is almost always formed from plastic. The plastic interior of a refrigerator is made using a process called vacuum forming. Large sheets of plastic are heated until soft, then pulled into a mould using a vacuum. Once cooled, the components are trimmed and fitted. Vacuum forming allow the interior to be formed as a single component with no joints, making it a very hygienic solution.

Once the inner cabinet is inserted into the outer housing, any necessary cables and tubes are inserted in between. The gap or ‘cavity’ is then filled with expanding Polyurethane foam which provides the insulation required to retain the cool temperature.

Did You Know?

Polyurethane foam is injected as a liquid, and over a short period of time (around 30 seconds), expands over 30 times its volume to fill the space between liner and outer case. The same process is used to insulate doors. The polymer foams right inside the refrigerator walls, and fills every nook and cranny, making it extremely airtight.

Cooling System

Once the cabinet is complete, the refrigeration components – that is, the compressor, evaporator, condenser and other components – are installed. These are typically fitted with the use of screws and clips. Copper tubing is used to connect the cooling system together. This tubing must be bent, soldered and coated at the joints to prevent leakage or corrosion.

A refrigerator works by removing the warmth from the air within its interior compartments and relaying that heat to the air outside. Beginning in the evaporator, the refrigerant gas is heated and begins to draw heat from the air within the refrigerator. Having absorbed this heat, the refrigerant is then routed to the condenser by the compressor. In this set of copper coils (usually mounted at the back or on the bottom of the refrigerator), the refrigerant returns to a liquid state, transferring its heat into the outside air as it does so. After cooling, the refrigerant returns to the evaporator, where the cycle begins again.

Source: https://www.madehow.com/Volume-1/Refrigerator.html#ixzz40tKQGyS8

Seals & Handles

Finally, the door seals and handles are fitted. The door seal or ‘gasket’ is typically formed with magnets inside to allow the door to seal fully when closed. The gaskets are screwed into place or fixed with a strong adhesive. The handles and hinges, which may be made of plastic or metal, are then screwed to the door and final calibration takes place to ensure smooth operation.

On some commercial models, a locking mechanism may also be incorporated. This is usually fitted externally.

Leak Testing

An important part of the manufacturing process is leak testing. This is usually first conducted using the relatively safe gas Nitrogen to ensure that the system is completely sealed. If no leakage is detected, testing will then take place with the final refrigerant.

At Carlton Services, commercial refrigeration is our speciality. Our team of expert engineers are accredited service agents for all the leading brands, and with over 35 years in the business our knowledge is almost unrivalled.

To discuss your service needs, find your local service center here or give us a call on 01793 512550. Alternatively, submit an enquiry online and we’ll get back to you as soon as possible.

References

*https://www.polyurethanes.org/index.php?page=refrigeration-and-freezers

https://www.ior.org.uk/ior_/fantastic_fridges_site/science/how%20your%20fridge%20works.htm